In the world of ultramodern manufacturing, the perfection and effectiveness of ministry play a pivotal part in determining the quality and product speed of colorful products. Among the most important machines in the electric motor industry is the hub motor winding machine. This machine is essential for winding the coils that are used in mecca motors, which are crucial factors in electric vehicles( EVs), bikes, and numerous other operations taking high necklace, compact size, and energy effectiveness. With its fast and accurate winding capabilities, the hub motor winding machine ensures the product of high- performance motors that meet the strict demands of moment’s request.

Significance of Hub Motor

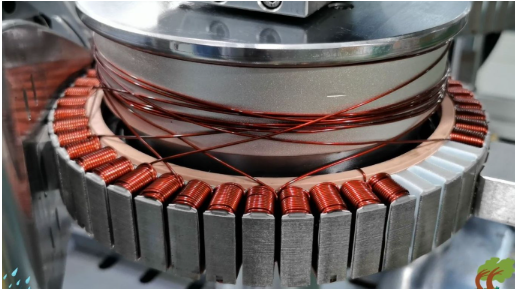

The hub motor winding machine is designed to give both speed and perfection in the winding process. In mecca motors, the winding of the stator is a critical step, as it directly affects the motor’s effectiveness, power affair, and trustability. A motor winder machine facilitates the robotization of this process, icing that the coils are wound with exact specifications. The effectiveness of this process is vital for the overall performance of the motor, making it a vital piece of outfit in diligence like electric vehicle manufacturing, renewable energy, and other sectors that calculate on high- performance motors. The motor winding equipment’s capability to handle a variety of motor sizes and winding configurations further increases its versatility and value in the manufacturing process.

Fast and accurate winding

- Increased effectiveness in motor product

- Essential in operations like electric vehicles and renewable energy systems

- Able of handling colorful motor sizes and configurations

Features and Benefits

Motor winding equipment, similar to the hub motor winding machine, is equipped with several advanced features that enhance productivity and maintain quality control. These machines generally feature automated line feeding systems, malleable winding pets, and precise pressure control. As a result, the product process is briskly and more accurate than traditional homemade winding styles. The machine can also be programmed to wind coils in different patterns or configurations, making it largely adaptable for different motor types. Likewise, the automated nature of the motor winder machine reduces the threat of mortal error, icing an advanced thickness in product quality and reducing destruction of accoutrements .

Speed and Precision

One of the name rates of a hub motor winding machine is its capability to produce high- quality windings at a rapid-fire pace. Speed is a critical factor in mass product surroundings, where manufacturers need to meet high demand with minimum lead times. The hub motor winding machine achieves this by using precise controls to wind coils snappily and efficiently, icing that the stators are produced in a bit of the time it would take manually. still, speed should noway come at the cost of perfection, and this is where the advanced motor winding equipment excels. With its slice- edge technology, the machine can wind coils with exact specifications, icing that each stator is impeccably aligned and able of delivering optimal performance in the finished motor.

Reducing Labor Costs

Another significant advantage of using a motor winder machine is the reduction in labor costs. In traditional manufacturing setups, homemade winding is labor- ferocious and requires professed workers to insure quality. still, with the arrival of motor winding equipment, these tasks can be automated, significantly reducing the need for homemade labor. As a result, manufacturers can save on labor costs while adding product capacity. The time savings also contribute to briskly product development, helping companies meet growing demand while maintaining profitability. also, since the machine operates continuously with minimum time-out, it ensures that the product process remains smooth and continued.

Customization and Inflexibility

Hub motor winding machines offer great inflexibility when it comes to customizing the winding designs for different types of motors. Whether manufacturers are working on small mecca motors for electric bikes or large mecca motors for electric vehicles, the motor winding equipment can be acclimated to suit the specific winding conditions. Some machines come with programmable settings that allow manufacturers to alter the number of coils, winding pressure, and subcaste configurations depending on the motor design. This rigidity ensures that manufacturers can produce a wide range of motors without the need for investing in separate outfit for each design, streamlining the product process and perfecting cost- effectiveness.

The part of robotization

Robotization is a crucial benefit of ultramodern motor winder machines. By using automated processes, manufacturers can greatly reduce the threat of mortal crimes that can do during the winding process. crimes similar as inconsistent coil placement, incorrect winding pressure, or uneven layering can lead to motors that perform inadequately or fail precociously. With the hub motor winding machine, these issues are minimized as the outfit is programmed to execute precise movements and insure the correct specifications are met. This trustability is especially important in diligence like electric vehicles, where the performance of the motor directly impacts the safety, effectiveness, and overall success of the product.

- Robotization Reduces mortal Error Automated processes in ultramodern motor winder machines minimize the threat of mortal crimes during the winding process.

- Prevents Inconsistent Coil Placement robotization ensures precise coil placement, precluding crimes that could lead to motor performance issues.

- Eliminates Incorrect Winding Pressure The machine maintains the correct winding pressure, barring the threat of indecorous winding that could affect motor effectiveness.

- Ensures Indeed Mounding Automated control systems guarantee that the motor coils are wound with indeed layering, reducing the chances of faults.

- Improves trustability The machine’s programming ensures that all specifications are met, minimizing blights and enhancing product quality.

- Enhances Safety in Electric Vehicles In diligence like electric vehicle manufacturing, automation plays a critical part in icing motor safety, effectiveness, and trustability, eventually supporting product success.

Manufacturing Processes

To further enhance product effectiveness, the hub motor winding machine can be integrated with other manufacturing processes. For illustration, after winding, the stators can be tested for quality, and the machine can indeed be part of a completely automated product line that includes assembly, testing, and packaging. This integration helps reduce running time, icing that factors move seamlessly through the product stages. The capability to connect with other machines also allows for the collection of real- time data on the winding process, which can be used to fine- tune machine settings and farther optimize performance.

Conclusion

The hub motor winding machine is a critical piece of outfit for the future of electric motor product. With its capability to give fast, accurate, and effective winding processes, this motor winder machine enables manufacturers to meet the growing demand for high- performance motors. The combination of speed, perfection, cost savings, and inflexibility makes it an inestimable tool in the manufacturing of mecca motors used in electric vehicles and other operations. As the electric motor assiduity continues to evolve, the hub motor winding machine will remain at the van of invention, enabling manufacturers to stay competitive in a presto- paced and ever- changing request.